There are many potential wins for your event in working with an energy consultant: reduced fuel burn and, therefore, lower emissions outputs and costs; integrating renewables, mains and hybrid systems into your energy mix and data gathering for post event reporting. But who to hire? Individual consultant or a consultancy business? In this guest blog, Tim Benson shares his thoughts on the pros and cons of both and what professional credentials and skillsets you should be looking for.

The demand for energy consultancy services across the event and screen sectors in the UK is rising sharply. Speaking personally, across the three companies that I represent (Smart Power, ZAP Concepts and Showpower Global), we are currently providing energy consultancy services to Netflix, Red Bull, Coldplay’s MoTS tour, Live Nation and BMW. Also, notably, the BBC Sustainability Team have just appointed their own internal energy consultant to work across their live events and studio teams.

Energy consultancy, when delivered well, can lead to reduced fuel burn and, therefore, lower emissions outputs; it can help identify opportunities for integrating renewables, mains and hybrid systems into the energy mix and provide robust data for post event reporting. For those of you considering bringing in a consultant, here’s a few ideas on what you should you be looking for by way of professional credentials and skillsets.

Firstly, ask yourself whether you want to contract a consultancy business or an individual. The former will undoubtably be more expensive but comes with the benefit of greater resource. Businesses will typically charge a project fee, whilst freelance consultants often prefer a retainer or hourly fee payment model.

Next up, you should consider project scope and ask yourself whether you want a consultant who is simply going to observe, record and report, or do you want more of a consultant/facilitator, who will assist you with implementing a sustainable energy action plan. If the latter, then you need to understand how they approach risk management. An element of risk is implicit when deploying new technologies, especially in energy management. A good consultant/facilitator will help you weight up the pros and cons of taking said risks, perhaps in the first instance identifying areas of site where you can afford to take these risks in the name of R&D, before applying them more widely and for greater gains. With this in mind, it is definitely worth asking candidates whether they have any professional indemnity cover.

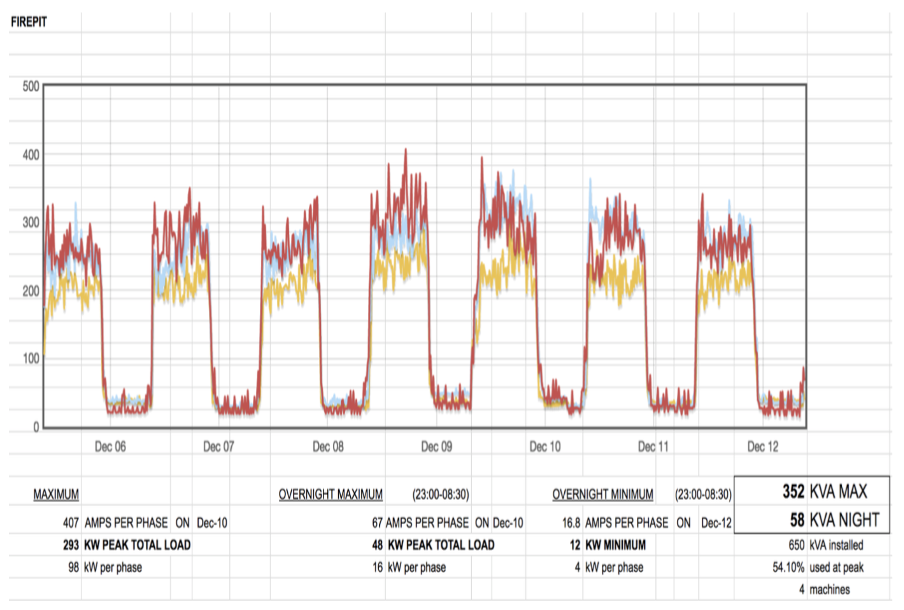

Also, if you are in the early stages of your energy efficiency journey, you might want to consider whether it is sensible use of financial resources to bring in a consultant purely for benchmarking. The kind of basic benchmarking data that you need before you can start setting improvement targets can usually be provided by your incumbent power contractor. This can then be shared with a consultant for analysis and the subsequent creation of an action plan with practical improvement strategies.

Having identified the consultant’s scope of work, now comes the difficult task of identifying appropriate candidates and shortlisting the most promising individuals. Obvious things to look out for include industry experience, employment history, client testimonials and any relevant materials they might have published, for instance contributions to industry reports. Such things can usually be found on LinkedIn profiles or through a consultant’s website. However, I would argue that a personal recommendation from a colleague pretty much always counts for more than anything gleaned from social media pages. Also, be wary of candidates whose work experience is limited to just a few companies. Very often they have been schooled in what I refer to as ‘catalogue power delivery’. They have always worked from a prescribed list of equipment, with a handful of selected third party suppliers, and their approach to power management can be overly formulaic. Your ideal candidate will be someone with extensive experience of working with multiple indie power contractors, across the full gamut of event types, and with a track record of integrating new technologies.

Once you have created your final candidate shortlist, then you need to start asking the more telling questions, most of which can be answered through reviews of redacted reports from historical projects that a consultant has worked on. Is there clear evidence of how they have delivered on client KPIs; is the language they use appropriate for the intended report audience; and is technical data presented in an intelligible manner.

However, as a final thought, I would proffer this – the most telling thing when assessing potential candidates is the kinds of questions they ask of you. They should definitely be enquiring about your motivation for hiring them in, what your overall objectives are, what deliverables you are expecting of them, what the perceived barriers are to achieving these and who the key project stakeholders are. If they are asking these kinds of questions, then you know they are serious about finding practical solutions that will get you from where you are to where you want to be.

This guest blog originally appeared in the May 2024 Vision: 2025 newsletter. Sign up to receive monthly event sustainability news, case studies and guest blogs direct to your inbox www.vision2025.org.uk