Greenbelt Festival Aim for 100% Sustainable Power

Greenbelt is a weekend festival of ‘arts, faith and justice’ that has been running since 1974. In 2017 they had 11,000 people onsite for the 4-day event. Greenbelt has strong commitment to creating an environmentally sustainable festival by making their site more power efficient and looking for renewable sources of power.

After moving site to Boughton House, Northamptonshire, in 2013 they went from a festival site that was partially powered from the grid to one that required 100% onsite power. Initially they used diesel generators festival to power the site but they are now, “working towards a future when the festival is powered entirely from sustainable sources,” says Event Director Mary Corfield.

Helping the Greenbelt team on this journey is production company Judgeday and power supplier Gofer Ltd, who began working with the Greenbelt team in 2016 to help them achieve their sustainability goals around power. At the 2016 event they saved 2,000 litres of fuel and for 2017 they carefully planned their power needs saving a further 16% on fuel usage.

They achieved this through careful planning, understanding that, “data is knowledge,” they worked with their traders, suppliers, concessions and artists to get a clear picture of their expected power needs across the site. This knowledge allowed Gofer to model their event power use and create ‘power zones’, enabling them to reduce the size of generators, and in some cases clustering them together so that smaller generators could be used at times of low demand. They also continued to use LED festoon lighting and switched to LED floodlights to reduce power demand.

During the 2017 festival Greenbelt had two dedicated team members who monitored power use across the site to record power peaks and lows at different times of day and in different locations. This data gave them a practical understanding of energy demand throughout the festival and has allowed them to put energy efficiency plans in place for the next season with real confidence.

For the 2018 festival they are switching two whole areas from diesel to solar powered and two further areas will be powered with hybrid generators. They will replace half of their diesel tower lights with solar and the other half will be swapped for LED flood lights.

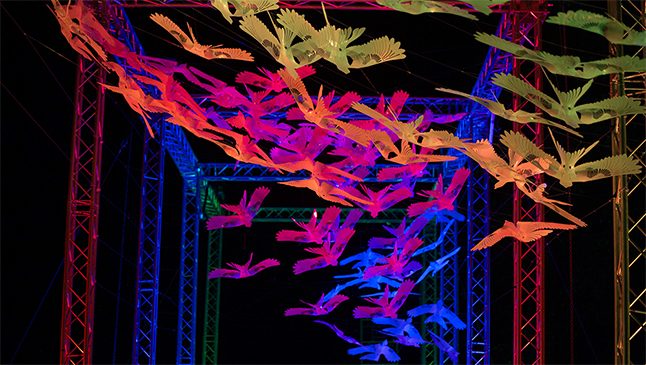

To reduce both transport costs and waste they rent an area on the site all year round to store staging, décor and furnishings. They have a policy of recycling and repurposing materials used in previous years and they have switched to generic (rather than year/theme specific) signage, which means they can be used year on year.

To further minimise waste Greenbelt has a re-usable cup scheme in their beer tents; their caterers use 100% compostable packaging work and food waste is collected and redistributed to local food bank charities. Greenbelt won a Greener Festival Awards in 2014, 2016 and 2017 for their environmental initiatives and they are part of the Vision: 2025 community of UK festivals who are working to reduce their environmental impacts. They also work with charity, Energy Revolution, to tackle the CO2 emissions associated with their audience travel by investing in projects that create renewable energy.

They have been recognised in the industry for their commitment to social inclusion and were awarded the Act of Independence award at AIF congress in 2017 for showcasing Muslim art and culture and platforming of Palestinian artists and activists. They hold the Gold Level on the Charter of Best Practice by ‘Attitude is Everything’ for their commitment to improving access for deaf and disabled festivalgoers.

The Greenbelt team believe passionately in the ability of individuals to come together and impact their communities and environment in a positive way; they plan to continue monitoring their environmental performance, innovating to find sustainable solutions, and sharing their experiences with the festival industry.